9.6 Industrial Minerals and Aggregates

Metals are critical for our technological age, but a lot of other not-so-shiny materials are needed to facilitate our way of life. For everything made out of concrete or asphalt, we need sand and gravel. To make the cement that holds concrete together, we also need limestone. For the glass in our computer screens and for glass-sided buildings, we need silica sand plus sodium oxide (Na2O), sodium carbonate (Na2CO3), and calcium oxide (CaO). Potassium is an essential nutrient for farming in many areas, and for a wide range of applications (e.g., ceramics and many industrial processes), we also need various types of clay [3].

The best types of aggregate (sand and gravel) resources are those that have been sorted by streams. In Arizona, the most abundant and accessible fluvial deposits are in the “Basin and Range” province, along the streams of the Salt River and the Gila River. Every building activity, from homes to skyscrapers, from roads to bridges, and from dams to power plants, requires these natural stone and mineral products. Sand is used to make glass, but for most types of glass, it has to be at least 95% quartz, and for high-purity glass and the silicon wafers used for electronics, the source sand has to be over 98% quartz.

Industrial minerals are geological materials mined for their commercial value, which are not fuel and are not sources of metals (metallic minerals) but are used in the industries based on their physical and/or chemical properties.

Aggregate is a broad category of coarse to medium grain particulate material used in construction. This includes sand, gravel, crushed stone, slag, recycled concrete, and geosynthetic aggregates. Aggregates are the most mined materials in the world.

Rocks are quarried or mined for many uses, such as building facades, countertops, stone floors, and headstones. In most of these cases, the favored rock types are granitic rocks, slate, and marble. Quarried rock is also used in some applications where rounded gravel isn’t suitable, such as the ballast (roadbed) for railways, where crushed angular rock is needed.

How does metal mine production compare to industrial mineral production?

In 2020, the estimated value of non-fuel mineral production in the U.S. was $82.3 billion. The estimated value of metal production was 27.7 billion. Curiously, the pandemic produced increased prices for precious metals, such as gold, which reached a record-high price of $2,060 per troy ounce. The total value of industrial mineral production was $54.6 billion. Almost a half of this value, 27 billion, was produced by construction aggregates (construction sand and gravel and crushed stone). The crushed stone had a production value of $17.8 billion in 2020 and accounted for 22% of the total value of U.S. non-fuel mineral production (U.S. Geological Survey, 2021).

In 2020, 12 states each produced more than $2 billion worth of non-fuel mineral commodities. These states were, in descending order of production value, Nevada, Arizona, Texas, California, Minnesota, Florida, Alaska, Utah, Missouri, Michigan, Wyoming, and Georgia. Construction sand and gravel and crushed stone are among the top mineral products of Arizona. In 2020, Arizona was the third producer in the country (California and Texas were 1st and second) (U.S. Geological Survey, 2021).

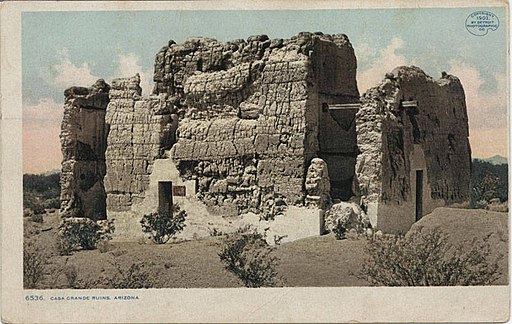

Backyard Geology. Casa Grande Ruins

The Casa Grande Ruins defeat the passage of time and weathering agents. Built about 1350, the ruins are testimony of the engineering techniques, material science, and astronomical knowledge held by ancient desert dwellers. The builders used caliche, a concrete-like mix of sand, clay, and calcium carbonate for the walls. The mineral layer covers juniper and pine tree timber that make up the skeleton of the structure. Saguaro ribs and reeds were covered with the caliche to form the roofs. Can you imagine the work it took to build a three-story structure without modern power tools, cranes, transportation, or wheels? An entire village remains covered by dirt around the major structure (Casa Grande), which may have been a cultural or knowledge center for the community. The Casa Grande Ruins are now a National Monument, protected from the elements by a steel-and-concrete canopy built in 1932. The ancient people of the desert continue to teach and amaze us with their accomplishments and knowledge.

Evaporites

Evaporite minerals, like halite, are used in our food as common table salt. Salt was a vitally important economic resource prior to refrigeration as a food preservative. While still used in food, now we mainly mined it as a chemical agent, water softener, or a de-icer for roads. Gypsum is a common nonmetallic mineral used as a building material, being the main component of drywall. It is also used as a fertilizer. Other evaporites include sylvite (potassium chloride, KCl) and bischofite (magnesium chloride MgCl), both of which are used in agriculture, medicine, food processing and other applications. Potash, a group of highly soluble potassium-bearing evaporite minerals present in Arizona, is used as a fertilizer. In hyper arid locations, even more rare and complex evaporites, like borax, trona, ulexite, and hanksite, are found and mined [1].

Potash, an evaporite

The term Potash refers to manufactured or mine salts with high concentrations of water-soluble potassium (K). Potash is an important ingredient for fertilizers. Arizona has a significant deposit of potash in the east-central part of the state, near and below the Petrified Forest National Park. The salt accumulated in the Holbrook basin during the Permian (~290-245 million years ago). The potash (KCl) is at the top of a much thicker halite (NaCl rock salt) deposit. The salt deposit is what is left of an ancient sea that inundated the area. Sodium is required for a wide range of industrial processes, and the most convenient source is sodium chloride (rock salt).

Currently, the Arizona potash deposit is not mined. Most of the potash used in the U.S. comes from two mines in southeastern New Mexico. Two companies operated two underground mines and one deep-well solution mine.

To learn more, read this article by the Arizona Geological Survey: Arizona has Potash!

Gypsum

Demand for gypsum depends principally on construction industry activity, particularly in the United States, where the majority of gypsum consumed is used for agriculture, building plasters, the manufacture of portland cement, and wallboard products. In 2020, domestic production of crude gypsum was estimated to be 22 million tons, with a value of about $190 million. The leading crude gypsum-producing states were estimated to be Iowa, Kansas, Nevada, Oklahoma, and Texas (U.S. Geological Survey, 2021).

NaCl

A salty, halide mineral that is often colorless or white. Halite is commonly known as rock salt and used globally as a condiment. It tends to form as cubic-shaped grains or crystals.

Areas that were depressed and accommodated and accumulated sediment